What is PET plastic?

Since David Attenborough spoke about the effect plastic packaging has on our environment in ‘The Blue Planet’, there has been a lot of discussions regarding plastic. Along with discussion, there has also been confusion. This blog will break down and supply information on the material HLP Klearfold use, how it is formed, used and recycled.

PET plastic, short for polyethylene terephthalate, is a raw material and is globally recognised as a safe, non-toxic, strong, flexible material which is 100% recyclable. PET is the most common clear packaging material and is used in day to day products. PET plastic is easy to recyclable with over 67% of all local authorities now offering collection facilities for these plastics. PET plastic can also be recycled at all recycling banks and centres. With PET plastic being so easily recycled and the ability for it to have an optimised lifespan, plastics can be re-used and recycled in all sorts of different items.

By recycling and reusing PET plastic as many times as possible reduces the need to produce more plastic material, meaning we are able to not only reduce the consumption of the energy used in the production of new plastic but also reduced the amount of solid waste that goes into landfill.

How is pet plastic recycled?

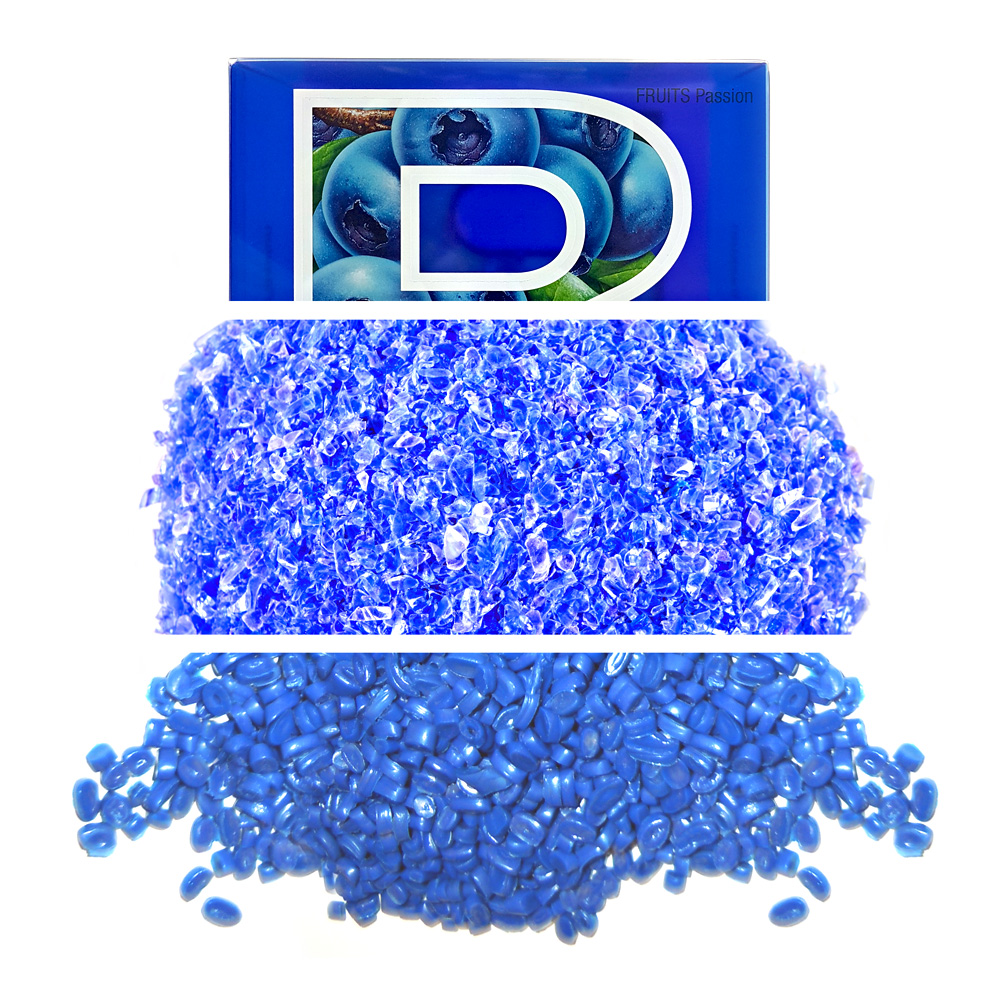

Once PET plastic has been sorted and separated from other plastics, it goes through several stages for it to be fully recycled.

• Shredded

• Washed

• Melted

• Pelletised

And then made into a new product.

Products that are made from recycled plastic:

• Trainers

• Pet beds

• Carpets

• Bottles

What material HLP Klearfold offer:

APET: (polyethylene-terephthalate) – Considered by many as an ideal material for plastic packaging with excellent clarity and print surface at a good price. Produced with 100% naturally occurring ingredients.

RPET: (recycled polyethylene-terephthalate) – An eco-friendly option of plastic material that offers excellent clarity and a similar print surface to PET. Produced with 30% post-consumer PET waste.

PETG: (polyethylene-terephthalate glycol-modified) – This modified version of PET offers high impact resistance but is not as easy to print on as other materials. Produced with 100% naturally occurring ingredients.

PP: (polypropylene) – The lighter option at 35% less weight to other materials with very good flexibility at a good price. Produced without water and zero harmful emissions.

Get in touch with us today to learn more about HLP Klearfold and the materials we use for our clear packaging.